Modbus TCP/IP: The Backbone of Industrial Automation

Modbus TCP/IP Client Chips are specialized hardware components that provide reliable, high-speed connectivity to modern industrial control networks. Modbus TCP/IP is the ubiquitous, open standard for communication in Industrial IoT (IIoT), SCADA systems, and Building Management Systems (BMS), using standard Ethernet as its transport layer (typically over Port 502).

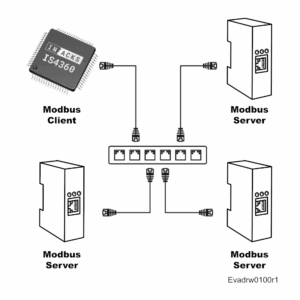

These Client chips act as the Master device, initiating requests to Modbus Server devices (PLCs, VFDs, sensors, gateways) to read or write data registers. Our components ensure seamless data acquisition, remote control, and monitoring by managing the entire process of frame construction, transaction identification, and data handling required to execute standard Modbus function codes like Read Holding Registers and Write Single Coil.

Hardware Acceleration for Industrial Protocol Stacks

Implementing a robust Modbus TCP/IP Client requires simultaneous management of a complex, resilient TCP/IP network stack (including socket and error handling) and the precise Modbus application layer logic. This dual requirement places a heavy burden on the host microcontroller, consuming significant resources and requiring specialized firmware expertise.

INACKS integrated circuits and modules help a lot to develop products with this category because the dedicated hardware offloads the entire network and Modbus stack, which avoids the firmware engineer to have to implement by itself the protocol. The host MCU only needs to issue high-level commands via a simple interface (such as SPI or UART), leaving all complexity to the specialized chip. This optimization results in less costs for specialized networking and protocol engineering and ensures the final, protocol-compliant product can be delivered sooner.