# IS4310: A Ready-to-Use Modbus RTU Slave Chip That Cuts Firmware Development Time

Modern embedded systems increasingly rely on industrial communication protocols. Among these, **Modbus RTU** remains one of the most widely used due to its simplicity, reliability, and broad adoption in PLCs, HMIs, industrial controllers, and SCADA devices.

However, implementing a robust Modbus RTU slave stack from scratch is time-consuming and error-prone.

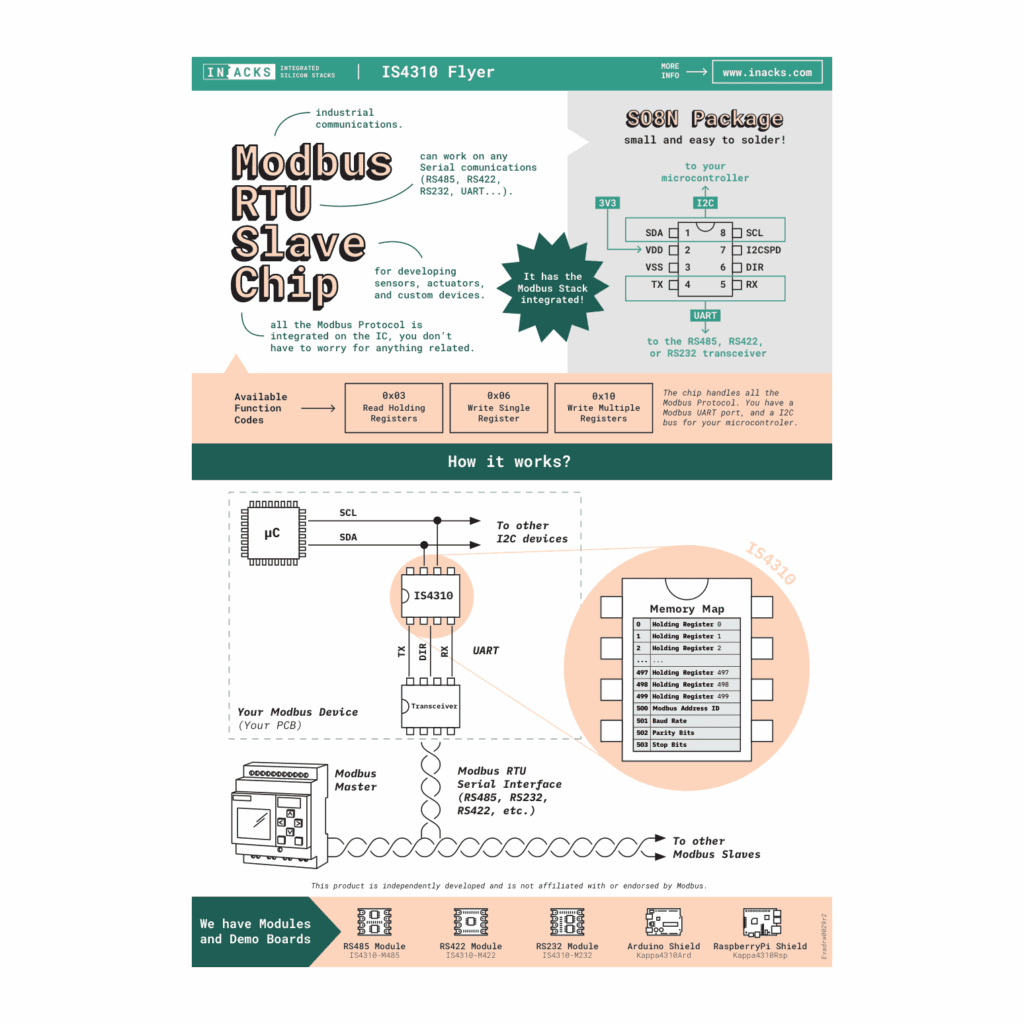

This is where the **[IS4310 Modbus RTU Slave IC](https://www.inacks.com/product/is4310)** becomes a highly efficient solution. It integrates a fully validated Modbus RTU stack inside a compact chip, allowing designers to add Modbus functionality **without firmware complexity or protocol debugging**.

—

## What Is the IS4310?

The **IS4310** is a dedicated communication-protocol IC that incorporates a complete **Modbus RTU Slave** stack. Developers only need to connect it to their microcontroller through a simple **I²C interface**, while the Modbus Master (PLC, PC, gateway, etc.) interacts with it over a UART-based RS485/RS422/RS232 link.

This architecture removes the burden of writing, validating, and maintaining a Modbus RTU implementation on the MCU.

For product details and documentation, visit:

https://www.inacks.com/product/is4310

—

## 500 Internal Holding Registers for Easy Data Mapping

A key feature of the IS4310 is its **500 internal Holding Registers**. These registers act as the shared memory space between:

– The **microcontroller**, via I²C

– The **Modbus Master**, via UART/RS485/RS422/RS232

This dual-access approach offers a clean, hardware-assisted separation between internal application logic and external Modbus communication.

### How it works

– Your firmware reads/writes the Holding Registers using **I²C** commands.

– A PLC or Modbus Master reads/writes the **same registers** via Modbus RTU.

– The IS4310 handles protocol parsing, CRC, timing, and frame management automatically.

This drastically reduces software complexity, especially in timing-critical environments.

—

## Flexible UART Interface for Any Electrical Standard

The IS4310 includes a UART port that can be paired with any electrical transceiver, such as:

– **RS485** – ideal for multi-drop industrial networks

– **RS422** – reliable for long-distance point-to-point communication

– **RS232** – perfect for local or legacy systems

This flexibility makes the IS4310 suitable for a wide range of industrial and commercial products.

Learn more about INACKS communication chips:

—

## Why Embedded Developers Choose the IS4310

### 1. Saves Engineering Time and Development Costs

Implementing a Modbus RTU slave from scratch involves:

– Frame parsing

– Error handling

– CRC generation/validation

– Timing windows

– Address management

– Interoperability testing

The IS4310 eliminates all of this. Your MCU only communicates using simple I²C register access.

The result: **lower development cost and faster time-to-market (TTM).**

—

### 2. Reduces MCU Resources and Pin Usage

The IS4310 offloads all Modbus timing and frame management. This means:

– No MCU timers needed

– Lower CPU load

– I²C can be shared with other peripherals

– No UART peripheral consumed by Modbus

Even tiny microcontrollers can now offer industrial communication reliably.

—

### 3. Guaranteed Protocol Reliability

Because the Modbus RTU stack is integrated and pre-tested, developers benefit from:

– Stable and predictable behavior

– No timing glitches

– No hidden bugs from custom firmware

– Immediate interoperability with PLCs and HMIs

This makes the IS4310 a **production-ready** communication solution.

—

## Typical Applications

The IS4310 is a perfect fit for:

– Industrial sensors

– Actuators and valves

– Motor and pump controllers

– Building automation modules

– Power monitoring devices

– Environmental measurement systems

Any device that needs Modbus RTU can integrate the IS4310 without firmware complexity.

—

## Key Technical Features

| Feature | Description |

|——–|————-|

| **Modbus RTU Slave Stack** | Fully integrated, no firmware implementation needed |

| **500 Holding Registers** | Accessible via I²C and Modbus RTU |

| **UART Interface** | Connects to RS485/RS422/RS232 transceivers |

| **MCU Interface** | I²C communication |

| **CPU Offload** | IS4310 handles protocol timing, CRC, and parsing |

| **Fast Integration** | Minimal firmware effort |

| **Reduced TTM** | Faster product development and release |

—

## Conclusion

The **IS4310 Modbus RTU Slave chip** eliminates the challenges of Modbus implementation in embedded systems. With a built-in 500-register memory map, simple I²C MCU interface, and flexible UART connectivity, it provides a reliable, ready-to-use solution for industrial communication.

Developers can:

– Shorten development cycles

– Reduce firmware workload

– Improve protocol reliability

– Bring products to market faster

Explore the IS4310 now on INACKS:

https://www.inacks.com/product/is4310